INSTRUCTIONS FOR KIENINGER MOVEMENT PF-43 IN WALL CLOCK CASE

This applies in general to other makes as well

To place the clock onto a wall – a good guide would be for the dial to be at head height.

Drill a hole ( or two holes for 8 mm wall plugs in the exact distance of the hangers, if your case is quite heavy.)

Insert round-head screws ( not countersink types ) Best would be as for pictures, to have them a little angled up. Check with a spirit level across. Adjustments can be made with one screw slightly thicker / thinner or filing out one of the slots a little to come to the correct level for the clock. Basically the case should appear plum to the eye. The screws only have to stick out about 15 mm.

It is a good idea to have 4 distance pieces at the back of the case to avoid possible condensation between wall and clock. If you have a rough brick / stone wall, you might have to level that with some spacer, as the clock should not wobble easily. ( dissipating the pendulum swing )

Winding: The clock should run about 10 to 12 days on one wind. In the normal running, springs will not be completely without tension. At those last 1 to 2 turns there is not enough power in the springs.

In that state you wind both sides ( left is the strike ) about 7 half turns. Counting half turns because you re-grip after every half. Then check that the clock runs 7 to 8 days. Best set a pattern for winding, e.g. every Saturday or whatever you want. You will get a feeling for this and if you notice over the weeks, that winding gets a bit harder at the end, then you can give it 6 half-turns for a while. That means you don’t put undue stress onto the spring-ends.

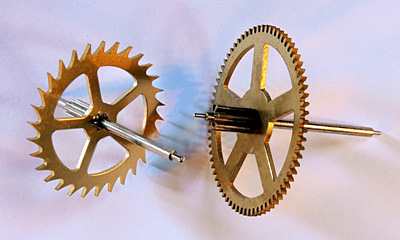

One important matter: before you finish each ½ turn, go slow and let the ratchet-pawl properly engage with the ratchet wheel.

You don’t see those mechanics, so here I illustrate a winding mechanism of a tower clock. ( I had hoped that the video clip can be directly viewed here, but it seems to need downloading – have to check with my webmaster.

( The Evangelical Lutheran Church in Strand Street, Cape Town ).

The end of the 6 seconds, 1.2 MB clip shows you what I mean.

link to follow here

Beat adjustment: Once the clock is on the wall, insert the pendulum hook into the square space of the suspension rod, best to hold it on the hook at the two screws. Swing the pendulum gently, so that the ticking just continues. Listen carefully that this is even – not “limping”. If it does “limp” to one side, unhook the pendulum, and lead the suspension rod to the side it limps. (that is further than the normal movement of the pendulum)

When you come to a stop, press the suspension rod carefully a fraction further.

Re-hang the pendulum, swing it and listen as before. Repeat if necessary or if you overdid it, do the same adjusting to the other side. One could do this with the pendulum in place, but your fine feeling might be impeded.

Regulating the clock: When regulating turn the rating nut beneath the disc. One turn will give a change in time-keeping of ca. 1 minute in 24 hours. You will find out the exact rating. (Up – to make it faster, lower -slower).

Hand-setting: You can set the time by turning the minute hand forward or back. One can do that without stopping at the half hour to let the clock strike. However if you come to a sudden resistance, do not force the hand further, but lead it back a little and let the strike run its turn, then move on.

Don’t set the clock fast forward over 12 o’clock, but let it strike there fully. That’s just a precaution.

Should the clock strike the wrong hour consistently (e.g. 4 x on 2 o’clock, 5 x on 3 o’clock etc. which means that the hour hand has been moved on the round shaft inadvertently) simply move the hour hand to the number just struck. Then adjust the time via the minute hand.

The hour hand has a round bush sitting on a round shaft. (with a fair amount of friction)

The minute hand has a square hole.

You can adjust the time forward or back when the clock is not in striking mode. (Also not at ca. 5 min. before the hour and half-hour.)

Strike switch-off: The short brass rod on the left is attached to a brass lever which lifts the hammer. Pull down to stop the strike and push up to resume. The strike train wheels will still move.

Service and maintenance: The clock movement should be cleaned, checked and re-oiled after ca. 4 years by a qualified clockmaker, not necessary a complete dis-mantling. That I recommend after another 4 year period.

Should you have touched brass parts, e. g. the pendulum disc or the grid, wipe the metal with a dry clean cloth, but do not use strong solvents, (cleaning benzene can be used if necessary on the lacquered brass parts).

Thomas Niemeyer, July 2018

e-mail: thomas@niemo.co.za